|

|

Post by justbuggin2 on Jun 19, 2012 23:00:03 GMT -6

way cool keep up the great work that is on the way to be one great ride

|

|

Junior

Currently Offline

Posts: 117

A+'s: 1

Joined: Jan 9, 2012 18:18:11 GMT -6

|

Post by dryshave on Jun 20, 2012 17:04:48 GMT -6

Thanks for following along guys and YES--- that is one big honkin' horn, though the wide angle lens does make it look bigger than it actually is. The horn is from the original elite 250, twice the size of the regular horn on a 150. Thought I'd update some pics of the front panel assembly. I'm slowly getting the two panels to match up. It takes a long time, shave a little, put it back together, then shaving a little more. I'm not planning on using the 10 mm nuts you see in the photos... once all the mounting points have been perfectly fit and the fiberglass lip has been cast, then I plan to use round headed hex screws to lock them together. I'm not looking to disguise the fact that these are two pieces, but to make them as though they were riveted together, but more on that later. I'm adding a couple of mounting tabs under the signal (eyes) lights this weekend... back into the fiberglass. I'm also showing where the dash gauges mount. Looking to use a vintage replica set of gauges available online. The paper cutout shape that represent the positioning of the gauges, is to be cut out of a 5mm brass. These are still the big brush strokes, once I get into the bodywork, I will be able to bring out the finer details. Cheersh      |

|

Junior

Currently Offline

Posts: 117

A+'s: 1

Joined: Jan 9, 2012 18:18:11 GMT -6

|

Post by dryshave on Jul 11, 2012 16:46:52 GMT -6

|

|

|

|

Post by justbuggin2 on Jul 11, 2012 21:38:38 GMT -6

you are getting close to paint it is looking great and i know you are getting excited that it is getting closer to the finish

|

|

New Student

Currently Offline

Posts: 44

A+'s: 0

Joined: Jul 28, 2012 13:01:28 GMT -6

|

Post by SuperDaveGulvak on Jul 29, 2012 11:31:31 GMT -6

This thing is gonna be sick when you are done dude!

|

|

|

|

|

|

Post by justbuggin2 on Aug 3, 2012 20:00:47 GMT -6

there is a trem called engine turn that was used back in the day on sheet metal i think the dash brass panel will look killer with that done to it

|

|

Junior

Currently Offline

Posts: 117

A+'s: 1

Joined: Jan 9, 2012 18:18:11 GMT -6

|

Post by dryshave on Aug 9, 2012 18:28:26 GMT -6

Great suggestion justbuggin2... I had to google the term and I agree. It will look pretty killer done to the dash.

I've poured the plaster cast for the tail lights and plan to pull it tomorrow, then the whole make a positive - finish it - and take that to the friends at the foundry for casting.

Just got a call from the local honda centre and the cylinder has been bored (1 over) and new pistons/rings and all the other goodies will be back to me early next week. I am so looking forward to getting the engine bolted back together.

More pics next week.

|

|

|

|

Post by justbuggin2 on Aug 9, 2012 19:50:35 GMT -6

i am enjoying wacthing and reading this wish i could see it in person

|

|

Junior

Currently Offline

Posts: 117

A+'s: 1

Joined: Jan 9, 2012 18:18:11 GMT -6

|

Post by dryshave on Aug 30, 2012 21:06:03 GMT -6

|

|

Junior

Currently Offline

Posts: 117

A+'s: 1

Joined: Jan 9, 2012 18:18:11 GMT -6

|

Post by dryshave on Sept 25, 2012 17:12:42 GMT -6

Getting the motor back on friday, so I guess it's time to get back in the garage.

Sorry not much work done over the summer, busy gardening and building a greenhouse. But now that the engine is back in the mix... it's time to get busy with the bodywork. Pics of progress will be posted in a couple of weeks.

Working on how the panels attach to the frame and making sure that everything lines up correctly.

Cheersh!

|

|

|

|

Post by justbuggin2 on Sept 25, 2012 22:15:17 GMT -6

i am looking forward to seeing more

|

|

Junior

Currently Offline

Posts: 117

A+'s: 1

Joined: Jan 9, 2012 18:18:11 GMT -6

|

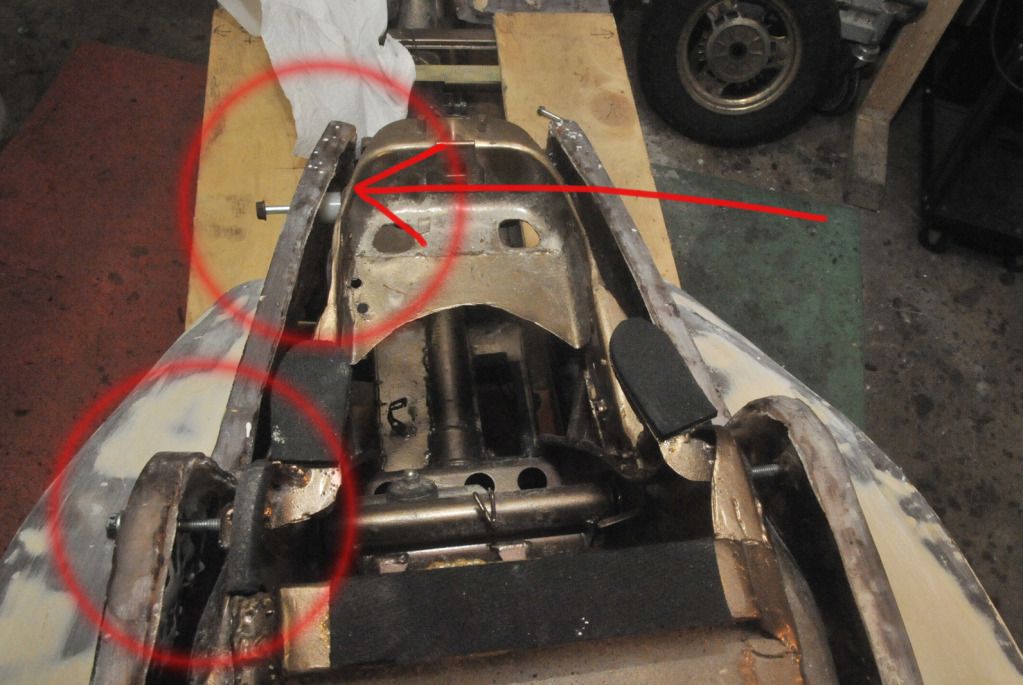

Post by dryshave on Oct 11, 2012 16:40:33 GMT -6

Summer's over.... and I'm back in the garage. Have glassed the mounting tabs into position and secured the rear tail section to the frame. I have used plastic spacers which I've collected (to build the support block) and glassed a large washer on the outer skin of the body (to add strength) as well. I used polyurethane glue to lock the blocks in place, then glassed all the way around it. No pics yet, but am taking some tomorrow morning. I've locked down the cast piece of white density foam and getting ready to start back in with the bondo. I've been checking L and R tolerances constantly and so far so good. The panels sit well and are relatively even... nothing bodywork won't fix. Next on to casting the mounting position for the front kickplate, I'll update that as well when I take pics over the weekend. Work now will be slow and laborious as the stage moves into final shaping and sanding on the body panels. Engine is back and I'm buttoning it up and getting ready to mount it back into the frame. Wiring harness done... Electronics mounted... Have to resize the battery tray (used a battery from a CH150 - DOH!) and looking to reposition the upper shock mounts to accommodate the phat rear tire that came with the Helix. Still considering going to the Helix front end and utilizing the 13" front wheel with disk brakes... but it's not in my radar yet. Good to be back in the shop... |

|

|

|

Post by justbuggin2 on Oct 11, 2012 21:26:21 GMT -6

still enjoy seeing what you are doing looks like you got things under control keep up with the great fab and soon it will be done

|

|

Junior

Currently Offline

Posts: 117

A+'s: 1

Joined: Jan 9, 2012 18:18:11 GMT -6

|

Post by dryshave on Oct 12, 2012 15:38:42 GMT -6

Having the plasticine around is sure handy for backspacing voids. You can see where I have blocked out the mounting plates for the front cowl to kick plate. I plan to glass over the plasticine (including the tab - seen on top piece). I had the brilliant idea to glass in a pop rivet mounting nut (used previously on the cowl - awesome invention) which I can then bolt right to the floorpan. Pics of the completed assembly will tell the story better than my description. Going to be a busy weekend inside, now that the rain and fall have finally arrived to the west coast. Decided not to paint the engine block, instead I'm just going to buff it with aluminum polish and a buffing attachment on a dremmel, can't redesign everything... |

|